In the current COVID-19 environment, we’re getting a number of requests from engineers to select energy recovery devices with minimal, or ZERO, cross contamination. At O’Dell, we’ve aligned ourselves with energy recovery partners offering multiple energy recovery device options. This “a la carte” approach to energy recovery allows us to specifically meet the requirements of each application. For the purpose of this post, I’m going to focus on technologies that offer near ZERO cross contamination.

<1.0% – Enthalpic Core, Fixed-Plate Heat Exchanger

- Cross flow design where the return/exhaust airstream is separated from the supply airstream

- <1% air crossover

- Polymer heat transfer material is waterproof, anti-microbial, and frost resistant

- ASTM viral penetration testing confirmed that viruses do not transfer through the heat transfer material. See report HERE.

- Transfers both sensible and latent heat

- Meets ASHRAE 90.1 effectiveness standards

- Has no moving parts for low maintenance

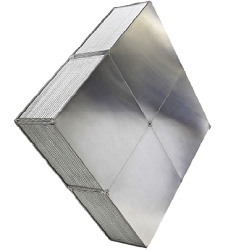

<0.5% – Sensible Core, Fixed-Plate Heat Exchanger

- Cross flow design where the return/exhaust airstream is separated from the supply airstream with aluminum substrate

- <0.5% air crossover

- Transfers sensible heat only

- Aluminum heat transfer material is strong and lightweight

- Has no moving parts for low maintenance

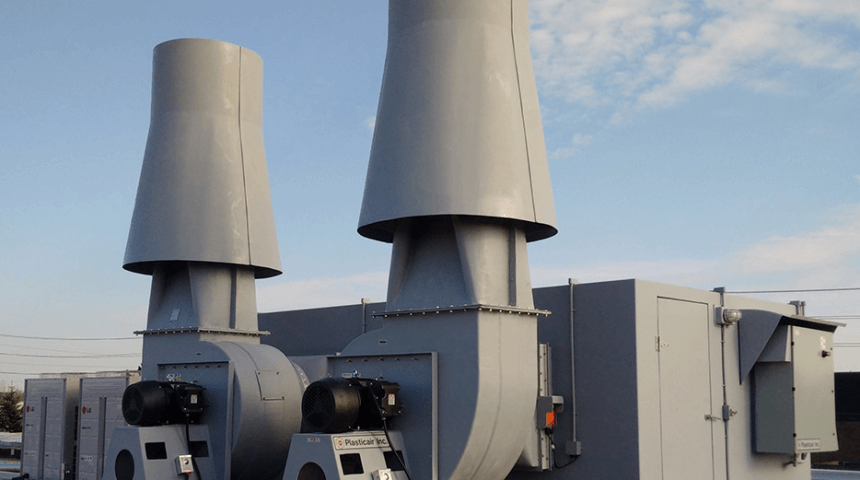

Absolute ZERO

When absolute ZERO is necessary, the only option is a split heat pipe or glycol run-around solution. These heat recovery technologies offer 20-40% efficiency and are typically only employed in lab environments.

Let O’Dell help you pick the right solution for your next project!