KML Windows, located in Strathroy, was expanding their manufacturing process to include a chemical dip tank that utilized a highly flammable solvent for treating wood. Recognizing the potential hazards associated with this addition, KML sought assistance from O’Dell and the engineering team at Integrated Engineering in London, ON, to create a comprehensive ventilation solution that would ensure a safe working environment while meeting regulatory standards.

Challenges

The introduction of the chemical dip tank brought several critical challenges that needed to be addressed to maintain workplace safety:

- Ensure a safe working environment for employees and the surrounding area

- Comply with the standards set forth in NFPA 34

- Utilize materials that were intrinsically safe and chemically resistant

- Achieve energy efficiency in the exhaust system

The Solution

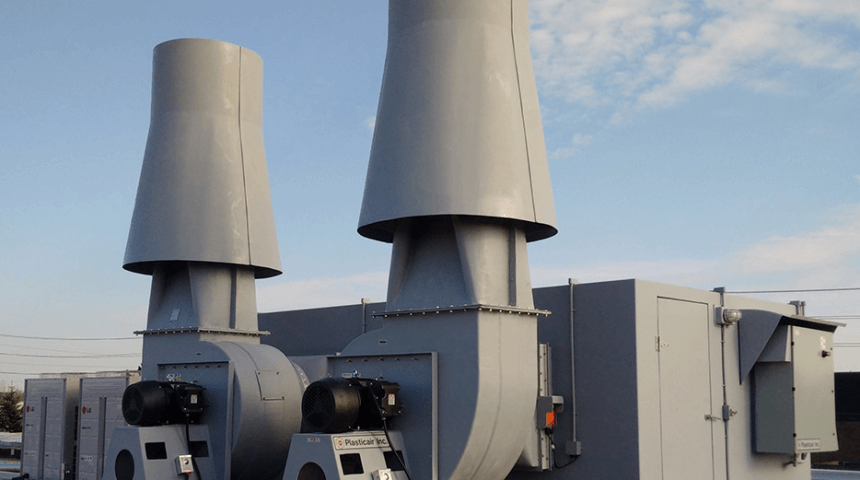

To meet these requirements, we collaborated with PlasticAir to design and supply two full fiberglass reinforced plastic (FRP) construction exhaust fans. The selected Skyplume fans featured:

- FRP Construction for enhanced resistance to chemicals and extended lifespan

- Induced flow nozzles to maintain a safe surrounding environment

- Plume height of 34.23 ft (10-MPH crosswind) to effectively disperse exhaust

- Dilution ratio of 284.76% to ensure proper mixing and reduction of hazardous vapors

- Graphite-lined, spark-resistant construction complete with a grounding kit

- Fans built to AMCA A spark-resistant construction standards

Initially, the plan called for a single, roof-mounted exhaust fan stack. However, to avoid costly structural enhancements to the roof, we opted for two smaller exhaust fans mounted on stands at the side of the building. This approach not only saved on structural costs but also provided redundancy in the exhaust system, significantly enhancing worker safety.

The two-fan arrangement was designed to operate only as needed to maintain safe vapor concentration levels in the workspace. Each fan was equipped with a variable frequency drive (VFD), allowing for adjustable exhaust airflow as required, which improved the overall efficiency of the system.

Our Approach

This solution effectively addressed KML Windows’ ventilation needs by:

- Enhancing employee safety in the presence of flammable materials

- Meeting NFPA 34 standards for ventilation and exhaust systems

- Providing a cost-effective solution without compromising safety or performance

- Improving energy efficiency through the use of VFDs for optimal airflow control