In the realm of building design and HVAC systems, optimizing ventilation is crucial for energy efficiency and occupant comfort. One key element in achieving this balance is the strategic design of exterior louvers. Several key features play a vital role in controlling airflow, preventing unwanted elements from entering the building, and reducing system static pressures. Join me as we explore the principles behind designing exterior louvers with the specific goal of minimizing static pressures within HVAC systems.

Understanding System Static Pressures:

Static pressure refers to the resistance to airflow in a ventilation system. High static pressures can lead to increased energy consumption, reduced system performance, and elevated operational costs. Exterior louvers can be instrumental in alleviating these issues by managing airflow and reducing resistance within the HVAC system.

Design Considerations:

1. Aerodynamics and blade profiles.

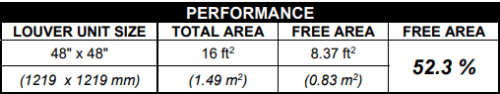

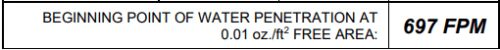

A) Free Area – The Free Area of a louver refers to the unobstructed cross-sectional area available for airflow and is crucial for accurately accessing its ventilation performance. When reviewing Free area data, it is important to understand the calculated information is commonly based on a sample of 48” x 48” or (1219mm x 1219mm ) – See Picture # 1 Below . The smaller the louver, the less free area will be available. As a result, static pressure can be easily affected if proper design is achieved. It is good practice to review the free area charts provided by manufacture ( see picture #2) Below.)

Picture 1

Picture 2

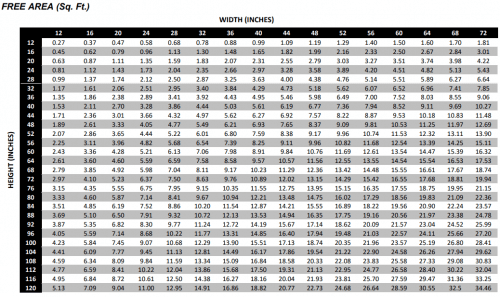

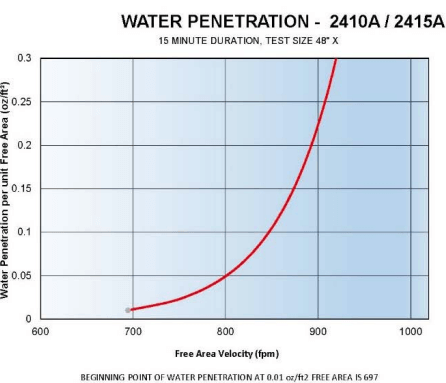

B) Water Penetration – Water Penetration of Louver refers to the ability of the louver to resist the ingress of rain or moisture, a critical factor in maintaining the integrity of building envelopes and preventing water damage. This data becomes very prevalent in intake applications and is a good starting velocity when designing the recommended free area required in a system. See picture # 3 below .

Picture 3

Picture 4

C) Blade Profile – The Blade Profile of a louver significantly influences its aerodynamic efficiency, allow for precise control of airflow, minimizing pressure drops, and enhanced overall performance in ventilation systems. Louver designs should complement the overall architectural aesthetic while facilitating optimal airflow. When choosing a blade it is strongly recommended to choose a manufacture that has certified 3rd part testing such AMCA 511 as the Ventex 2410A/2415A . See picture # 5 Below.

Picture 5

2. Material Selection:

- Choose materials that balance durability, aesthetics, and aerodynamic efficiency. Aluminum and stainless steel are commonly used for louvers due to their corrosion resistance and lightweight properties. However Galvanized Steel and CR Steel are available in custom several common blade profiles.

3. Adjustable Louvers:

- Consider incorporating adjustable louvers to provide flexibility in controlling airflow based on seasonal variations and HVAC system demands. This adaptability can help optimize system performance throughout the year.

4. Louver Orientation:

- Assess the prevailing wind direction and sun path to determine the optimal orientation of louvers. Proper alignment can enhance natural ventilation while minimizing resistance within the system.

5. Maintenance Accessibility

- Design louvers with ease of maintenance in mind. Accessibility for cleaning and inspection ensures long-term functionality and efficiency.

6. Bird and Insect Protection:

- Integrate features to prevent the infiltration of birds and insects. Mesh screens or specialized designs can be incorporated to maintain optimal airflow while keeping unwanted elements out. Keep in mind, AMCA testing data does not include the effects of Bird screen in the manufactures testing data.

Benefits of Optimized Louver Design:

1.Energy Efficiency:

- Reduced static pressures lead to improved energy efficiency, lowering overall operational costs and environmental impact.

2. Improved Indoor Air Quality:

- Effective louvers prevent the entry of pollutants, allergens, and outdoor contaminants, contributing to healthier indoor air quality.

3. Enhanced HVAC System Performance:

- Optimized louvers alleviate strain on HVAC systems, promoting longer lifespan and improved overall performance.

Conclusion:

Designing exterior louvers with a focus on minimizing system static pressures is a proactive step towards achieving energy-efficient and sustainable building ventilation. By integrating aerodynamic principles, adjustable features, and strategic orientation, architects and engineers can create a harmonious balance between form and function, ultimately enhancing the overall performance of HVAC systems while ensuring the well-being of building occupants.